Risø Nuclear Station left us with nuclear facilities to be dismantled and cleaned.

Danish Reactor 1

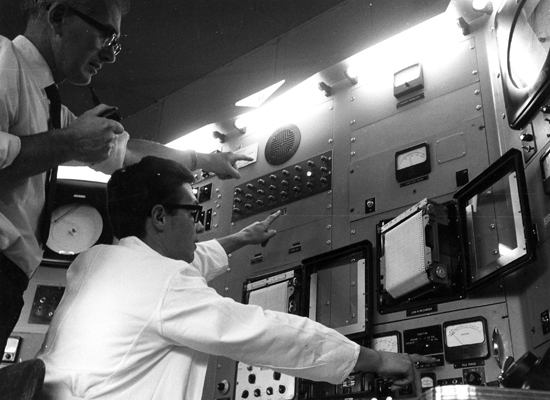

DR 1 was the first reactor at Risø Nuclear Station and was inaugurated in 1957 - the year before the official inauguration of the research centre. It was a low power reactor (max. 2 kW, equivalent to a hair dryer) with a relatively modest content of radioactivity.

The reactor core was contained in a spherical steel tank and consisted of an aqueous solution of uranyl sulphate with 20% enriched uranium equivalent to approximately 1 kg of U-235. The steel tank was surrounded by a cylindrical graphite reflector with a diameter of 1.5 m and a height of 1.2 m. Around the reflector there was a concrete shield.

In the latter years, DR 1 was primarily used for educational purposes and it was the last reactor to be taken out of operation in 2001.

DR 1 is fully decommissioned. In 2003, the uranium solution (the core fluid) was drained into steel bottles and the primary system was decontaminated by flushing it with water.

The actual decommissioning began in 2004. In August of that year, the control rods were taken out and put into storage. Then the most radioactive parts were removed: the recombiner as well as the core tank, which was lifted out of its graphite reflector. The work was done partly by remote control.

Subsequently, DR 1's reactor block was demolished. After cleaning parts of the concrete, the vast majority could be disposed of as ordinary construction waste during the summer of 2005 after thorough control measurements. This was the first released decommissioning waste to be taken out of the area.

In the autumn of 2005, measurements were made on the building according to set release criteria. Nuclear regulatory authorities approved the release measurements in January 2006. Today, the building is used by DTU for other purposes.

Danish Reactor 2

DR 2 was inaugurated in 1958. It was a 5 MW 'pool-type' light water reactor, i.e. open upwards so that you could look down to the reactor core through a few meters of water, which served as a refrigerant, moderator and radiation shielding.

The reactor was used for physics experiments and for the production of isotopes. It was ultimately shut down in 1975 and put into a state of safe enclosure.

The shutdown was due to the fact that the much larger DR 3 had sufficient capacity for the scientific tasks as well as the production of isotopes and other irradiation tasks.

DR 2 is fully decommissioned. The work took place from May 2006 and until the end of 2007. First, the vertical and later the horizontal test tubes were removed from the reactor block. The areas around the reactor were then cleared of old test tubes and other equipment from the reactor operation.

From October 2006 to March 2007, the inner parts of the reactor were removed; lead nose, graphite rods and grid plate. As the radiation level rises, the further towards the core one gets, the project required a number of control measurements, comprehensive safety assessments and detailed work plans.

In 2007, the company of G. Tcherning A/S was responsible for cutting down the reactor block. In 2008, the hall was cleared, and control measurements were made. The final report was approved by the nuclear regulatory authorities in December 2008, and at the same time the plans for converting the hall to a radioactive waste handling facility were approved. Today, Danish Decommissioning uses the hall to handle larger waste items.

DR 2 was inaugurated in 1958. It was a 5 MW 'pool-type' light water reactor, i.e. open upwards so that you could look down to the reactor core through a few meters of water, which served as a refrigerant, moderator and radiation shielding.

The reactor was used for physics experiments and for the production of isotopes. It was ultimately shut down in 1975 and put into a state of safe enclosure.

The shutdown was due to the fact that the much larger DR 3 had sufficient capacity for the scientific tasks as well as the production of isotopes and other irradiation tasks.

DR 2 is fully decommissioned. The work took place from May 2006 and until the end of 2007. First, the vertical and later the horizontal test tubes were removed from the reactor block. The areas around the reactor were then cleared of old test tubes and other equipment from the reactor operation.

From October 2006 to March 2007, the inner parts of the reactor were removed; lead nose, graphite rods and grid plate. As the radiation level rises, the further towards the core one gets, the project required a number of control measurements, comprehensive safety assessments and detailed work plans.

In 2007, the company of G. Tcherning A/S was responsible for cutting down the reactor block. In 2008, the hall was cleared, and control measurements were made. The final report was approved by the nuclear regulatory authorities in December 2008, and at the same time the plans for converting the hall to a radioactive waste handling facility were approved. Today, Danish Decommissioning uses the hall to handle larger waste items.

Danish Reactor 3

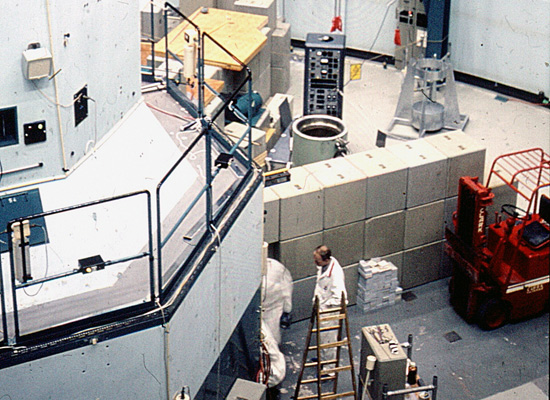

DR 3 was put into operation in 1960. It was a heavy water reactor with a thermal power of 10 MW. (By comparison, the Barsebäck 1 reactor was 1800 MW.)

The reactor was primarily used for basic neutron physics research, material research and production of isotopes for, for example, medical and industrial applications. DR 3 was known to be extremely reliable and attracted scientists from all over the world.

In addition, the reactor was used for neutron irradiation (doping) of silicon for use in the semiconductor industry. In the late 1990s, Risø held one third of the world market for neutron-doped silicon.

In the year 2000, DR 3 was shut down, initially due to suspicion of a leak in the reactor tank, but the shutdown ended up being permanent.

Following the shutdown of DR 3, all the fuel from 40 years of operation was returned to the United States by agreement. The actual decommissioning of the reactor is divided into two main phases, the first of which is completed. It involved the dismantling of the many peripheral systems of the reactor (cooling systems, experimental setups, pipes, electrical installations, etc.). The last peripheral system was dismantled in December 2011, while the heavy water compartment was dismantled the following year.

The second main phase of decommissioning is ongoing. This involves removing the inner parts of the reactor and dismantling the reactor block.

In popular terms, the reactor block is a 6 x 6 metres wide and 10 metres high steel and concrete box. Inside is a lead-lined steel tank of approx. 3 metres in diameter. Among other things, the aluminium reactor tank with a diameter of 2 metres and with a 30 cm graphite layer were placed in this.

In 2014, the reactor plug and its shielding ring were lifted off the top of the reactor tank. The reactor tank was then cut open with remote tools and this and the graphite layer were lifted away in 2018. Now the lead lined steel tank and the outer steel/concrete box are being sawn into blocks and removed. Finally, the reactor building needs to be cleared of fixtures, ventilation, etc. and cleaned before release measurements are taken.

Hot Cells

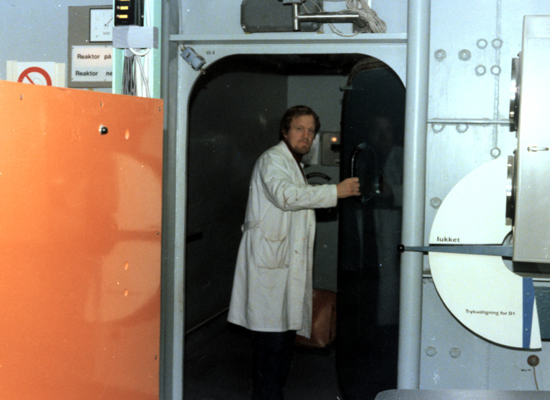

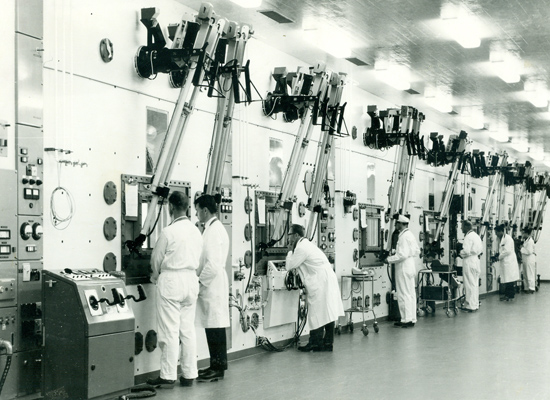

The Hot Cell facility consists of six connected concrete cells, which have been used for handling radioactive materials and studies on irradiated subjects. Among other things, experimental fuel from DR 3 and cobalt sources for the hospitals’ blood irradiation facilities have been handled and packaged here.

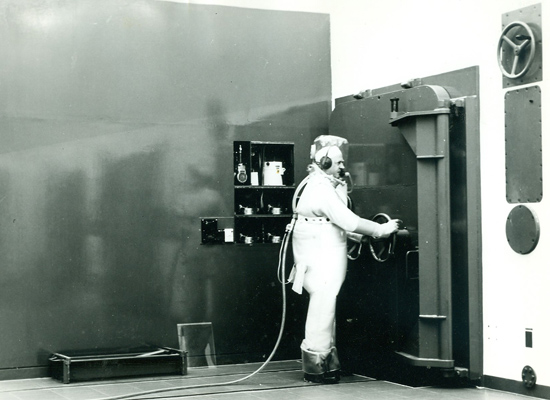

The outer walls of the cells are approx. 1.7 metres thick. The operators were standing outside the cells and used mechanical remote-control manipulators to carry out the work while monitoring it through a lead glass window.

The facility was in use from 1964 until 1989, where it was closed as a result of Denmark's decision in 1985 not to use nuclear power.

In 1990-94, the Hot Cells facility was partially decommissioned by attempting to clean three cells with water and dismantle all cell equipment, power and ventilation. Then, the row of cells was covered with a plaster wall and the adjacent areas were converted to office space.

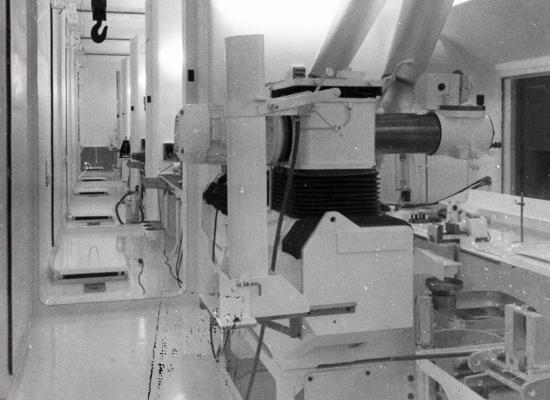

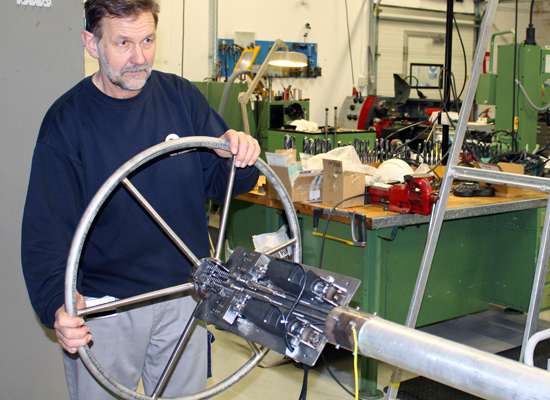

When the actual decommissioning was started in 2008, the first years were spent cleaning up and (re )establishing the necessary facilities. Now the primary task is to clean the contaminated cells. Due to the radiation level, the initial blast cleaning has been done with self-developed mechanical arms, which were pushed into the cells via holes in the 1.7 metre thick concrete walls. Inside the cells, the surfaces have been sandblasted, after which contaminated paint flakes and the sandblasting material have been exhausted.

The rough cleaning, which was completed in 2018, reduced radiation by approximately 85%. It is now possible for employees to spend short periods of time inside the cells.

The intermediate cleaning, which started in 2020, is primarily performed remotely.

Once the work inside the cells is complete, the concrete structure of the cells will be demolished and their peripheral installations will be decommissioned before final reports can be prepared and the building can be released.

The Hot Cell facility consists of six connected concrete cells, which have been used for handling radioactive materials and studies on irradiated subjects. Among other things, experimental fuel from DR 3 and cobalt sources for the hospitals’ blood irradiation facilities have been handled and packaged here.

The outer walls of the cells are approx. 1.7 metres thick. The operators were standing outside the cells and used mechanical remote-control manipulators to carry out the work while monitoring it through a lead glass window.

The facility was in use from 1964 until 1989, where it was closed as a result of Denmark's decision in 1985 not to use nuclear power.

In 1990-94, the Hot Cells facility was partially decommissioned by attempting to clean three cells with water and dismantle all cell equipment, power and ventilation. Then, the row of cells was covered with a plaster wall and the adjacent areas were converted to office space.

When the actual decommissioning was started in 2008, the first years were spent cleaning up and (re )establishing the necessary facilities. Now the primary task is to clean the contaminated cells. Due to the radiation level, the initial blast cleaning has been done with self-developed mechanical arms, which were pushed into the cells via holes in the 1.7 metre thick concrete walls. Inside the cells, the surfaces have been sandblasted, after which contaminated paint flakes and the sandblasting material have been exhausted.

The initial blast cleaning, which was completed in 2018, reduced radiation by approximately 85%. It is now possible for employees to stay briefly inside the cells. The more thorough cleaning, which will begin in 2020, will primarily be carried out with a remotely operated robot. When the work inside the cells is complete, the concrete structure of the cells will be demolished. In addition to this, all the established support facilities must be decommissioned, before final reports and applications for release of the facility can be prepared.

Fuel Fabrication Plant

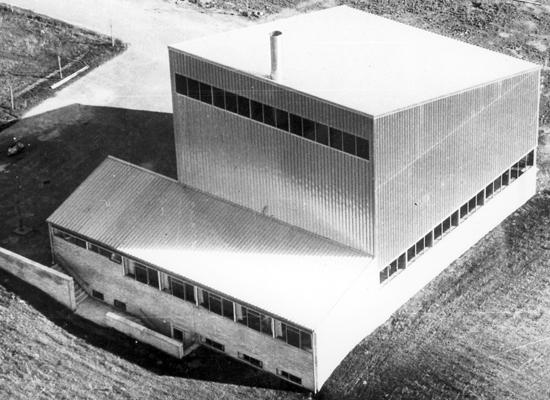

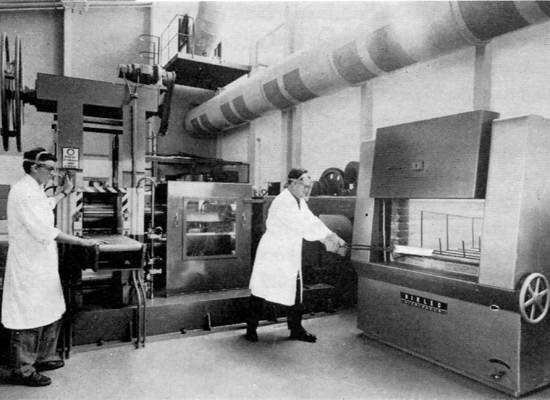

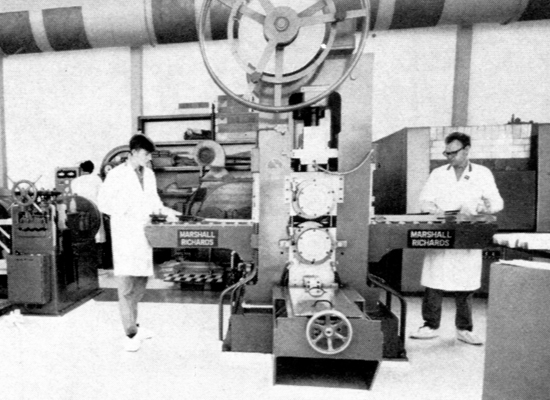

the Fuel fabrication plant is a former fuel factory where, from 1963, reactor fuel for DR 2 and DR 3 was produced using enriched uranium powder.

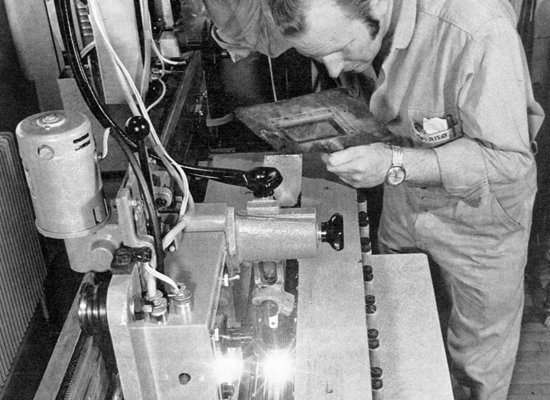

In the powder room, uranium powder was measured out and pressed into solid pieces. The powder was valuable and was carefully controlled, but it could not be avoided that small quantities of uranium were stirred up or lost. In the rolling mill, the uranium pieces were rolled into thin sheets encased in aluminium. Once rolled out, the uranium sheets were cleaned and degreased in, among other things, acid in the so-called cleaning room.

Until 1988, the entire fuel fabrication plant was used to manufacture fuel elements with highly enriched uranium. Later, only part of the hall has been used for the production of low-enriched uranium fuel elements; the remaining area was cleaned, measured for contamination and downgraded for use for other purposes. Production ceased completely with the closure of the DR 3 reactor in the year 2000.

The practical decommissioning of the Fuel fabrication plant was completed on May 1, 2023, when the building was released for unrestricted use.

The contamination in the hall consisted of non-irradiated uranium in the form of dust, powder and deposits on surfaces.

In the powder room, the entire room was sanded and the flooring, the ventilation and the drains were removed. At the rolling mill, there was no free-floating uranium around the roller, so this was a somewhat simpler task: in a distance of half a metre from the roller the flooring was removed, and the rolling mill itself was control measured. In the cleaning room, the cleaning tubs were removed, the walls were sanded down in a 70-cm belt all around the room and the flooring was removed.

In addition, a number of fixtures and equipment had to be removed from the building.

As the last task, there was a single issue with a slight contamination in a crawl space. Finally, both a technical and a health physics final report were written and approved by the nuclear regulatory authorities.

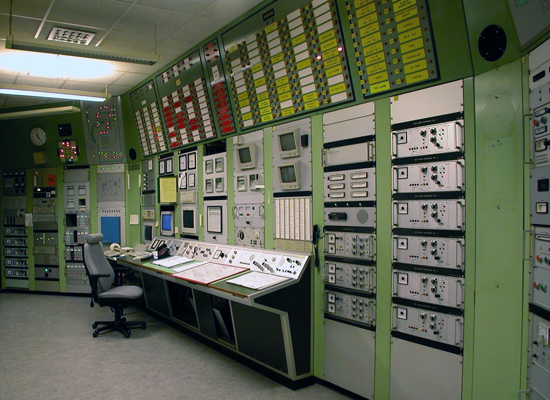

Waste Treatment Plant

The waste treatment plant is the only acknowledged recipient of radioactive waste in Denmark. It has a number of facilities for receiving, minimising and sorting, characterising, packing and storing the waste.

The radioactive waste comes partly from Danish companies and institutions and partly from the decommissioning of the facilities at Risø. After treatment, the waste is stored in drums and containers in temporary storage facilities.

Until 2020, the waste treatment plant housed a couple of laboratories as well as a laundry and sewing room for DD 's work clothes. Furthermore, a conventional sewage treatment plant for Risø is operated from here.

The waste treatment plant is to be decommissioned as the last of the nuclear facilities, as it is still used to process the waste from e.g. the other decommissioning projects. In preparation for its decommissioning, some of the facilities have been transferred to other buildings at Risø.

When a new, upgraded storage facility is ready for use, the radioactive waste will be transferred there from the current storage facilities, which will then have to be decommissioned.

Although the practical decommissioning of the waste treatment plant and the storage facilities has only just started, preparations have been underway for a long time. A project description has been drawn up and work has started on emptying the storages. In addition, a large part of Risø's underground piping and tank system, which collected the so-called active water for evaporation from, among others, cleaning cabins and certain washbasins, has been dismantled.

The waste treatment plant is the only acknowledged recipient of radioactive waste in Denmark. It has a number of facilities for receiving, minimising and sorting, characterising, packing and storing the waste.

The radioactive waste comes partly from Danish companies and institutions and partly from the decommissioning of the facilities at Risø. After treatment, the waste is stored in drums and containers in temporary storage facilities.

Until 2020, the waste treatment plant housed a couple of laboratories as well as a laundry and sewing room for DD 's work clothes. Furthermore, a conventional sewage treatment plant for Risø is operated from here.

The waste treatment plant is to be decommissioned as the last of the nuclear facilities, as it is still used to process the waste from e.g. the other decommissioning projects. In preparation for its decommissioning, some of the facilities have been transferred to other buildings at Risø.

When a new, upgraded storage facility is ready for use, the radioactive waste will be transferred there from the current storage facilities, which will then have to be decommissioned.

Although the practical decommissioning of the treatment plant and storages has only just begun, preparations have been underway for a long time. A project description has been prepared and work on emptying the storage facilities has started. Furthermore, a large part of Risø's underground pipe and tank system (for collection of the so-called active water from e.g. decontamination cabins and certain washbasins before evaporation at the treatment plant) has been decommissioned.