Aug 9 From concrete to radioactive waste

40x40x200 cm. barite concrete, 40x40x200 cm. radiation shielding or 40x40x200 cm. radioactive waste. What all the names have in common is that they describe the same blocks but at different points in their lifespan.

F

What they all have in common is that no matter what you call the 800 kilogram blocks that, piece by piece, leave the building that used to house Denmark's largest research reactor, the conclusion is the same. For the next several thousand years, the blocks will be laid to rest in a final repository, which will be completed by 2073 at the latest.

From 1960 - 2000, from tests to decommissioning

One of the major projects at Danish Decommissioning is the decommissioning of Danish Reactor 3 (DR3). A project that was initiated at the birth of Danish Decommissioning in 2003 and has been a central part of the organization's work throughout its 20-year lifespan.

The DR3 was finally completed and commissioned on January 16, 1960 and ran until 2000. The reactor design was purchased in England, and as part of this design, concrete was used as shielding. For 40 years, this concrete acted as a shield against the reactor's radiation and for more than 40 years, this concrete remained untouched.

From 2000 - 2023, from shielding to radioactive waste

After the decommissioning of DR3 in 2000, it was necessary to figure out what to do with the former experimental facilities at Risø. This led to the establishment of Danish Decommissioning on September 15, 2003, and since then work has been ongoing to decommission the six nuclear facilities at Risø.

Here it has become clear that the decommissioning of DR3 is a more complicated process than the decommissioning of Risø's other two reactors, DR1 and DR2. The reasons for this are many, including the fact that DR3 is a different design than the other two and that DR3 is significantly larger, both in power and thus also in radiation levels and physically, than the other two.

The fact is, however, that DR3 is undergoing decommissioning, and as part of this process, blocks of the aforementioned concrete are being cut into carefully measured pieces. Pieces that then need to be placed in a steel container and therefore need to be the right size. It's a time-consuming process that is complicated for a number of reasons.

The concrete can have pockets of shotcrete in it and rebar has been used to cast around it, which is extremely demanding on the blades used for this purpose. This means that there are days when saw blades need to be changed regularly. Up to 4 times a day.

All cutting is done in a closed cage with a remote-controlled saw to ensure as little dust inside the building as possible, but this also means that changing the blade takes time.

The aforementioned cages are connected to large vacuum cleaners, whose filters also need to be changed regularly, a change that can only be done while the saws are stationary.

But let's get back to the concrete blocks.

Once the concrete blocks are finally cut to size, they are ready to leave the cages and make their way to the steel container they will be in for the next thousand years.

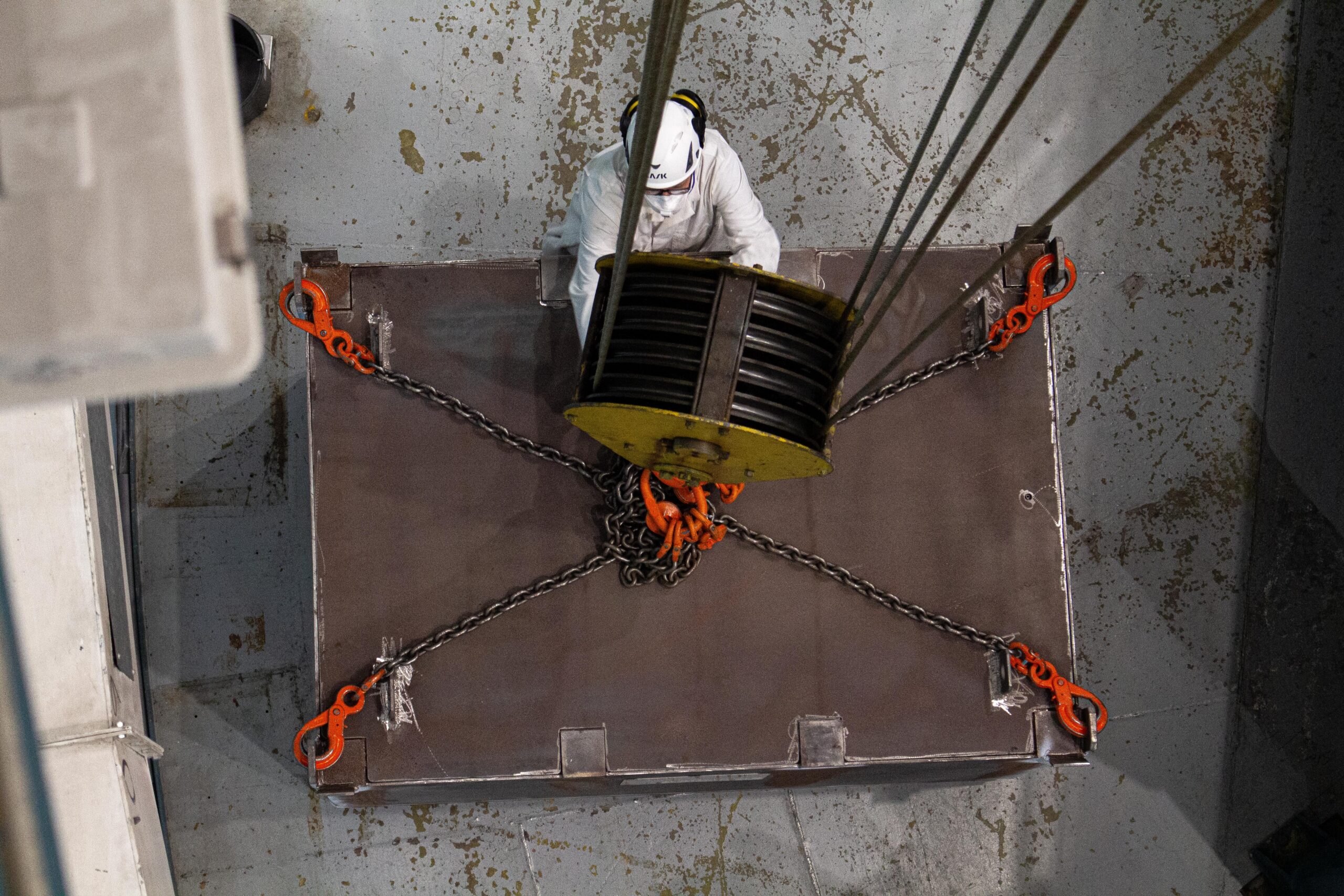

However, the blocks are so heavy that they can't just be lifted and therefore require lifting with the crane installed as part of DR3. A laborious lift that means that the blocks have eyelets drilled into them for lifting so that a tray can be placed under the block. Once this is in place and the block is set down, the tray with the block on it is lifted over to the steel container. Here, the tray is removed again and the concrete is lifted into the steel container, which is packed until it is completely full. That is, when 9 blocks are in the container.

It is also here that the now 63-year-old concrete is no longer shielding, but is now, and will forever be, radioactive waste.

2023 - ? A journey ends

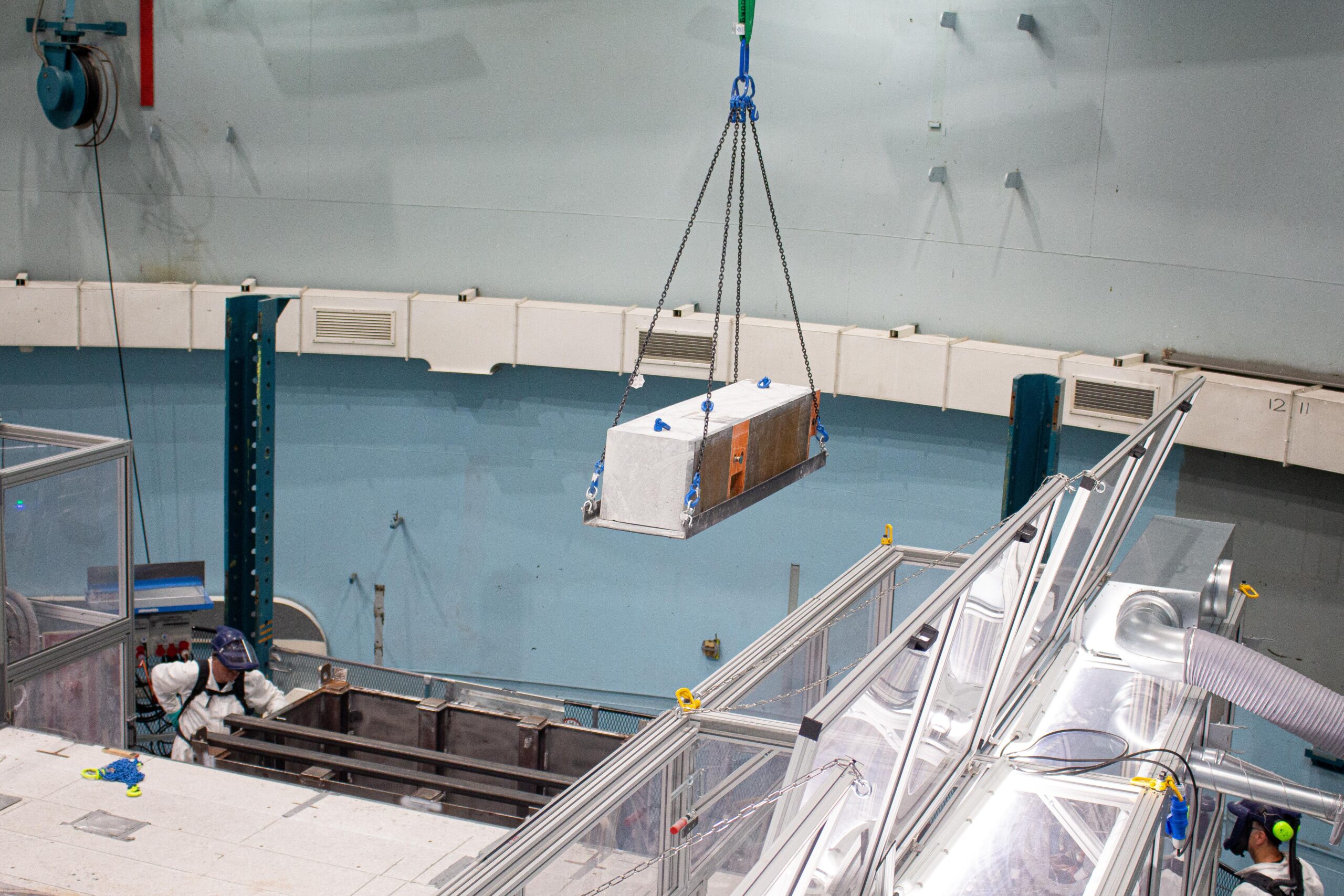

Once the blocks are neatly stacked in the steel container and the lid is put on, the container must be transported from DR3 to the intermediate storage facility, located approximately in the middle of Risø.

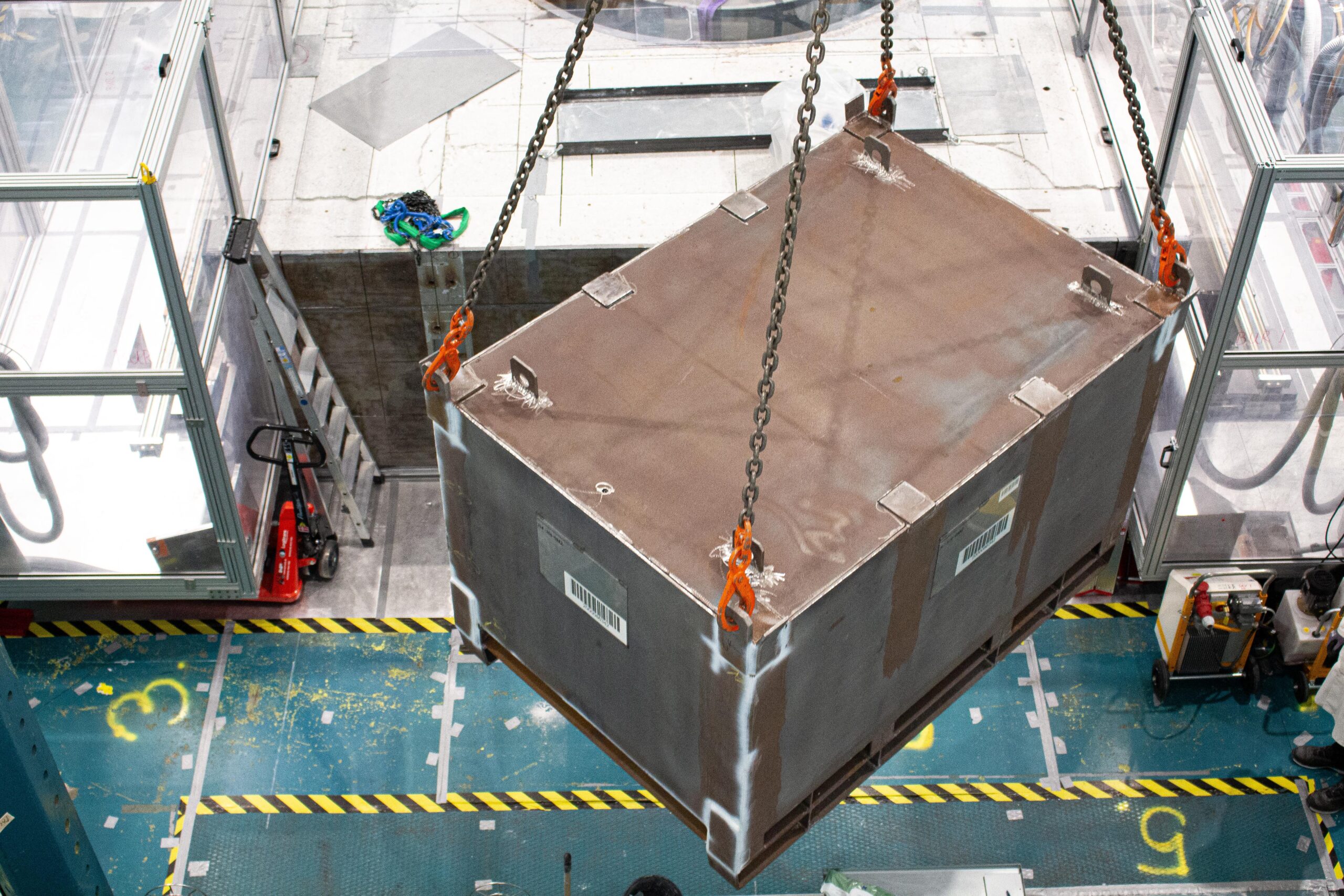

However, before they can make the trip, the radiation level of the waste must be measured. Even though the waste will eventually go to the final depot, and in the meantime will be stored in the interim storage facility, it is still necessary to know how much radiation the container radiates on the outside.

This is because it affects where the container is placed in the interim storage facility, for radiation levels outside the warehouse and as a future reference when the container is moved.

At the same time, the container also gets a barcode affixed to it, and it is created in the waste database, so it will always be possible to look up the container and get information about the contents, a maneuver that all radioactive waste at Danish Decommissioning has gone through.

A single container full of concrete blocks weighs more than 9 tons, so shipping it requires the right equipment in the form of cranes and transport trucks, but also a good deal of cooperation and skilled employees.

Once the container is placed in the interim storage facility, it will remain there until it needs to be moved again to the new upgraded storage facility (NOL), before eventually ending its days in a final depot, commissioned no later than 2073.