22 Dec Busyness, momentum and creativity characterised 2011

DD has been busy this year with three major projects and a number of smaller tasks. There has been both momentum in the projects and teasing with procurement, and sometimes thinking outside the box to solve the tasks.

22011 has been a busy and exciting year for DD , where the primary focus has been on three major projects: the Hot Cell plant, dr 3- the research reactor and feasibility studies for the final depot for radioactive waste. The year has offered both momentum and banter, and required flexibility and creative solutions.

One of the major milestones of the year for 2011 has been the dismantling of peripheral systems on research reactor DR 3. The milestone was reached when the last facility, boe (which cleaned helium tyre gas for the reactor), was removed on 13 December 2011. Now the reactor "naked" is left ready for the second phase, which includes removing the internal parts of the reactor (reactor tank, top shield, etc.) and decomposition of the heavy water space and the reactor block itself.

Throughout the year, the DR 3 group has prepared the comprehensive project description of phase two in parallel. The project description was approved by the nuclear regulators in December 2011 and have thus given the green light for the further liquidation of Denmark's last research reactor .

The second major project, the decommissioning of the Hot Cell plant, proved more difficult than anticipated and has also called for the use of non-traditional tools.

A Tank in Hot Cells

The cleaning of the six highly radioactively contaminated concrete cells was scheduled to begin in 2011. However, it proved more difficult to obtain the right custom and remotely operated equipment than first thought. Therefore, the project team has had to saddle up so that instead of cleaning the cells they have taken on tasks that should have been solved at a later date.

One of these tasks, the removal of the conveyor channel, required an alternative solution and help from the toy industry. In the Hot Cell facility, the approximately 30-metre channel runs under the tables across the cells. The channel has served for the transport of smaller items between the six cells. The transport has been carried out with the conveyor wagon, which can be driven back and forth in the conveyor channel by means of a chain pull.

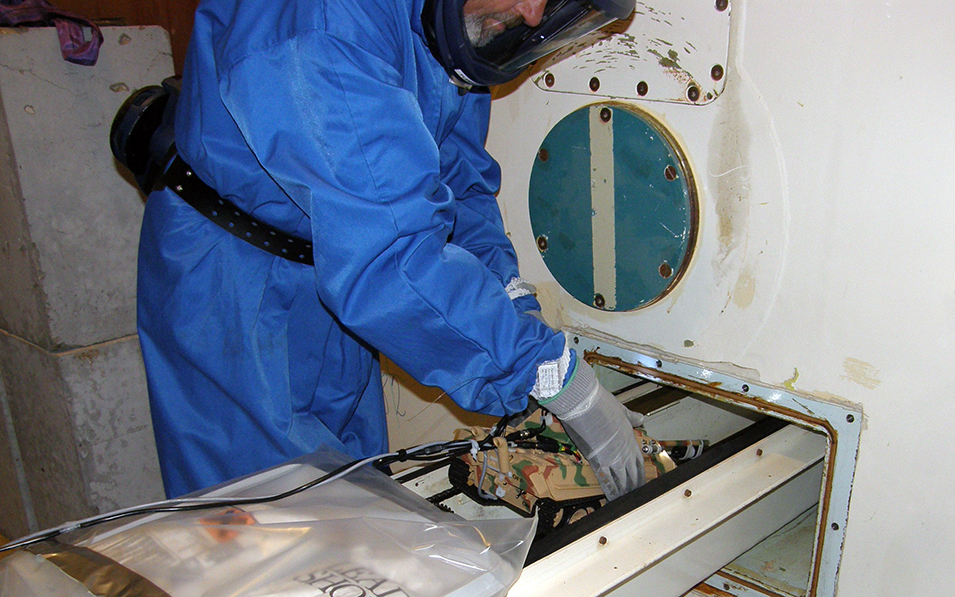

In preparation for the procurement, characterisation studies were carried out to determine the extent of radioactive contamination in the duct, including the presence of possible hot spots (very small particles with a high radioactivity content). As the canal is difficult to access both due to its size and location in the contaminated cells, the project had to resort to unconventional methods to detect the level of contamination. For this purpose, the DD 's workshop a remote-controlled toy tank, which was small enough to drive through the canal.

The tank was equipped with an extra-long wire, camera, light and radiation detector and sent in through the canal. The tank's patrol revealed that there were several "hot spots" in addition to one that appeared in the old documentation. The information is used to determine what safety measures are required when the channel is later removed from the installation.

Preliminary studies for final depot published

Another milestone DD in 2011, the publication of the preliminary studies was a final storage facility for radioactive waste. On Wednesday 4 May 2011, the partial reports were presented to the political parties and subsequently published on the Ministry of Health's website. The designation of 22 suitable and six recommended areas for the location of the final depot attracted a great deal of attention both in the media and in the municipalities concerned. DD in the ensuing period, was busy welcoming the media in order to showcase the radioactive waste and explain the background to the preliminary studies.

Everything suggests that 2012 will be just as busy for the company. The DR 3 project's first task will be the demolition of the heavy water space under the reactor block. For the Hot Cell project, the preparation and implementation of the remotely operated sandblasting of the paint on the inside surfaces of the cells, as well as the purchase of equipment to suck out the used blower and paint and transfer it to DD 's waste drums.