Dec 5th A glass house has taken shape

Sometimes you have to build up to break down. In any case, this is the case with research reactor DR 3.

E After removing the external systems, the DR 3 project team is now in the process of decommissioning the reactor block itself - a square, 6 x 6 meter wide and 10.5 meter high concrete tower with an aluminum tank inside. In 2014, the reactor's plug and surrounding ring were pulled up, and since then the tank has been closed with a moving lid that can be driven aside on rails.

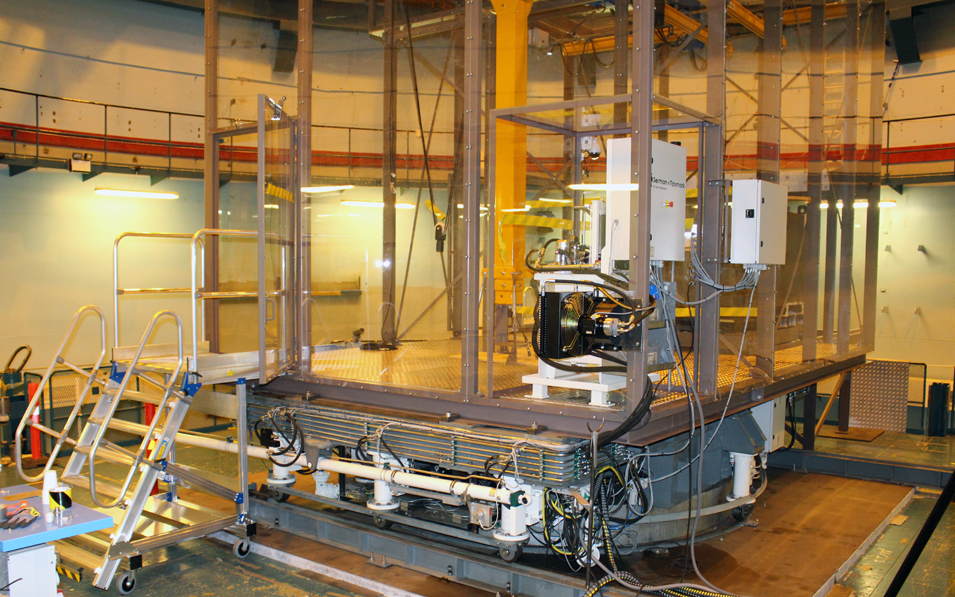

In autumn 2015, the reactor's top was equipped with a new clear acrylic edifice: two airtight, connected chambers mounted above the moving lid. The housing is to be used in the next big step in the decomposition process – cutting up the aluminium tank from the inside and removing the pieces one by one.

One chamber is called the manipulator housing and contains a remote-controlled hydraulic arm. The arm can be controlled down through the hatches in the moving lid and can be equipped with various tools to cut up the tank.

The second chamber is the so-called packing room, where a crane can lift up to 400 kg pieces of the tank and place them in a container. Once the container is filled and closed, the packing room can be opened and the container driven directly to the temporary storage facility on the Risø site.

Manipulator's house and packing room are custom made by Bladt Industries in Aalborg, which was also behind the moving lid. The remote control of the elements is thus co-or means – the manipulator arm, crane and the moving lid can all be controlled via one hydraulic station in the control room.

The plant is now awaiting approval by the authorities, and the tank could be turned into small pieces of radioactive waste.